- CONTACT

Postal code

1389915351

Phone

44904141-5 21 98+

Fax

44905541 21 98+

Email

info@itrac.ir

- ABOUT

Expanding the ability to perform tests required by domestic industries, especially the automotive industry based on national and international standards Identifying and evaluating the laboratory facilities available in the country in order to meet the needs of the automotive industry in order to help improve the quality of domestic products and facilitate exports. Cultivation and development of human resources as the main focus of increasing productivity Development of quality management system in order to provide customer satisfaction and gain international credit Cooperation and participation in the implementation of “research projects based on customer needs”

Providing effective laboratory, technical and engineering related services in various industries, especially the automobile industry, in order to meet the needs of customers to ensure the quality of products, as well as participate in optimizing the design and safety of products by taking advantage of the development and improvement of laboratory equipment, technology and World-class knowledge with the aim of meeting national and international standards

Obtaining the highest market share in providing laboratory services in the automobile, rail and other related industries in the country until the end of 1404

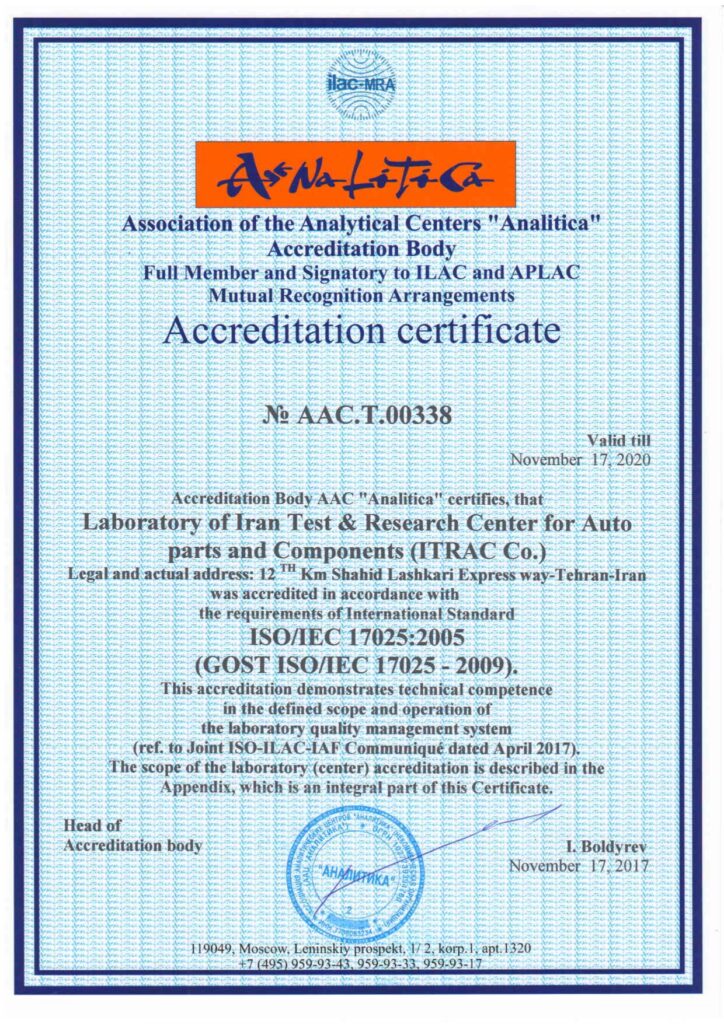

- CERTIFICATE

- LABRATORY

- HOME

Metallurgy Laboratory

Tests

Metal hardness testing in all scales: Vickers , Brinell ,knop ,Rockwell.

Microstructure and Metallographic tests with general light microscopes and scanning Electron microscope(SEM) such as:

Determination of Austenite and Ferrite grain size ,Inclusions content , Case depth and evaluation of Heat Treatment and process defects.

Mechanical testing of Materials as :Tensile and Impact.

Quality and thickness of different coatings.

Fractography, consideration of fractured surface to evaluate the probable causes of fracture with Stereo microscope and SEM.

Non-Destructive test: eddy current , Ultrasonic, Magnetic particles and Liquid Penetration on ferrous and non Ferrous parts.

Metal element analysis of Iron ,Aluminium , copper and zinc base alloy by optical emission spectrometery.

Attn: Ultrasonic and Eddy current Inspection and magnetic particles can be done by(professioned) persons with level 2 cerificate.

Reasearching tests as : Wear Resistance (Reciprocal and Pin on Disc Mecuanisms)and Hardenability of steels(JOMINY), Heat Treatment with furnace and salt bath in different cooling Media such as:Water, Oil and Air.

Different test to control quality of welding in from of non destructive or destructives.

Equipment

Wolpert Hardness tester up to 3000 kgf (Brinell, Rockwell and Vicker )

Wolpert hardness tester 10 gr to 10kgf( vicker and knop)

wolpert Universal hardness tester 1 kg to 250kgf ( Brinell , Vickers , SHIMADZU hardness tester Equo Tip

Image Analyser ZEISS microscope with magnification up to 1000X

Stereo Microscope LEICA with magnification up to 40X

scanning electron Microscopy (SEM) LEO with up to 300000 X magnification and ability to microanalysis

Ultrasonic Non-Destructive tests(STAVELVE)

Eddy current Non-Destructive tests(STAVELVE)

Magnetic Particles(KARL DEUTCH)

Tnsile test ZWICK 5 tons with extensometer

Tensile test WOLPERT 60 tons with extensometer

Wolpert Impact tester

Quantometer

General Description

Metallurgy laboratory is established to best services to Suppliers ,Producers ,Inspectors and Experts in Automotive Industry .It was accredited according ISO 17025 and participated in several proficiency tests with reliable European laboratories in different materials testing such as :

Hardness tests , Charpy Impact tests , Tensile tests ,Metallographic tests, metal analysis to improve the quality level of tests.